Please be aware of the detrimental effects that some chemical cleaners can have on Acrylic products, and in

particular window blades used in RV manufacturing.

Alcohol, certain tensides, organic solvents, softeners, to mention just a few, are considered corrosive. Furthermore

such products are potentially contained in plastic care products such as polishing pastes and care products for

rubber seals. Commercial window cleaners are usually made for glass not Acrylic/Perspex.

The official stance from Dometic Australia / NZ, is that only warm soapy water using dishwashing liquid in a mild solution

is suitable; use plenty of water. (Use this for the window blade and the rubber gasket that rests against the blade) Do

not wipe the windows dry. Talcum powder or white vaseline is OK for use on the rubber seals after cleaning.

To polish the windows after cleaning, Dometic only recommend Seitz Acrylic window polish (Order code – ZUB1343)

When cared for properly, Acrylic keeps its pore-free surface for years and does not turn yellow or brittle.

For information purposes, please refer to independent study link below showing how Acylic products can be

effected by certain chemicals.

http://www.eplastics.com/Plastic/plastics_library/Chemical-Resistance-of-Plexiglass-Acrylic

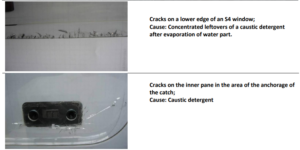

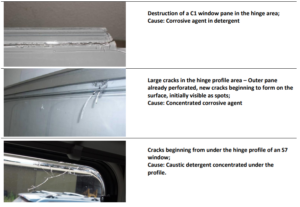

Problems that can occur include cracking of the window blades in various different ways as shown in photographs on

page 2. These cracks are not a manufacturing defect within the window, but are as a result of a chemical reaction to

inappropriate cleaning methods/chemicals being used. The cracks do not always appear immediately, and in fact

could take months or even years to appear depending on what has been used for cleaning.

The cracks can start forming in areas under high tension, for example, in windows in the areas near the hinge profile

or the catches. The formation of cracks is influenced by localised effects, time, corrosive element of the products

used and the temperature. In isolated individual cases there is only a localised formation of cracks on the surface or

in the corners.

When the corrosive agent is contained in the care product for rubber seals, the cracks form along the area on which

the seal comes to rest against the pane.

Examples of non – compatible cleaner types: